Matrix Tool started in a two-car garage in Erie, Pennsylvania in 1972 and has grown into a full-service provider of injection molding products and services. Please take a moment and review our history of sustained and continued growth. We appreciate all of the work from existing customers and hope to share our services with those looking for a tooling and molding partner!

Company History

1972

Matrix Tool, Inc. formed by David W. Lewis, Sr. & Robert D. Schuster in a two car garage in Erie, PA. with primary focus on mold repair and construction of mold components.

1973

Relocation of Matrix Tool, Inc. to 1848 West 21st Street. First full time employee was hired and services were expanded to include Mold Design and Mold Construction.

1976

Relocation of Matrix Tool, Inc. to present address at 4976 Franklin Road. Fairview, PA. Original site included a 2,000 sq. ft facility which was setup to complete Mold Design, Mold Repair and Mold Construction activities.

1977

First expansion of facility to accommodate additional dedicated space for Administration, Mold Design / Engineering and Milling / Manufacturing activities.

1984

Second expansion of facility to accommodate additional floor space for Surface Grinding & Die-Sink E.D.M. activities.

1989

Third expansion of facility to accommodate Plastics Injection Molding operations and allow dedicated space for the assembly, bench testing and in-house sampling of new molds.

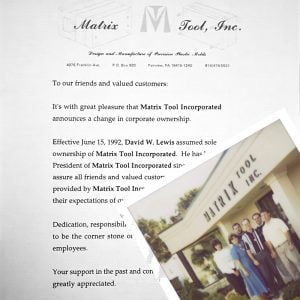

1992

Change in corporate ownership – David W. Lewis, Sr. assumes ownership of Matrix Tool, Inc. making the transition to a family business.

1992

Fourth expansion of facility to add dedicated space to support the expanding Mold Design / Engineering and Administrative functions.

1998

Fifth expansion of facility to add 30,000 sq. ft. of state of the art Molding Operation, to house 14 injection molding machines and to expand Tooling capabilities to include: Wire EDM, CNC EDM and High Speed CNC Milling technologies.

2000

Sixth expansion of facility to add dedicated space for Mold Changeover / Repair, Material Mixing and additional Warehousing and Quality Assurance. Facility size increased to 43,500 sq. ft.

2006

Seventh expansion of facility to add 13,600 sq. ft. of additional space to support Molding and Warehousing operations. The expansion allowed room for an additional 14 injection molding presses and increased the total facility size to 57,100 sq. ft.

2008

Eighth expansion of facility to add 2,500 sq. ft. of office space to support Plastics Engineering, New Product Development and Production Support functions.

2014

Interior renovation to repurpose 1,500 sq ft of warehouse space and transform it into a dedicated production area for small part/ micro molding advancements.

2018

Expansion of small part / micro molding production area through the repurposing and renovation of an additional 1,500 sq ft of warehouse space.

Present Day

Matrix Tool has evolved into a full service supplier, servicing the Precision Thermoplastic & Metal Injection Molding industry.