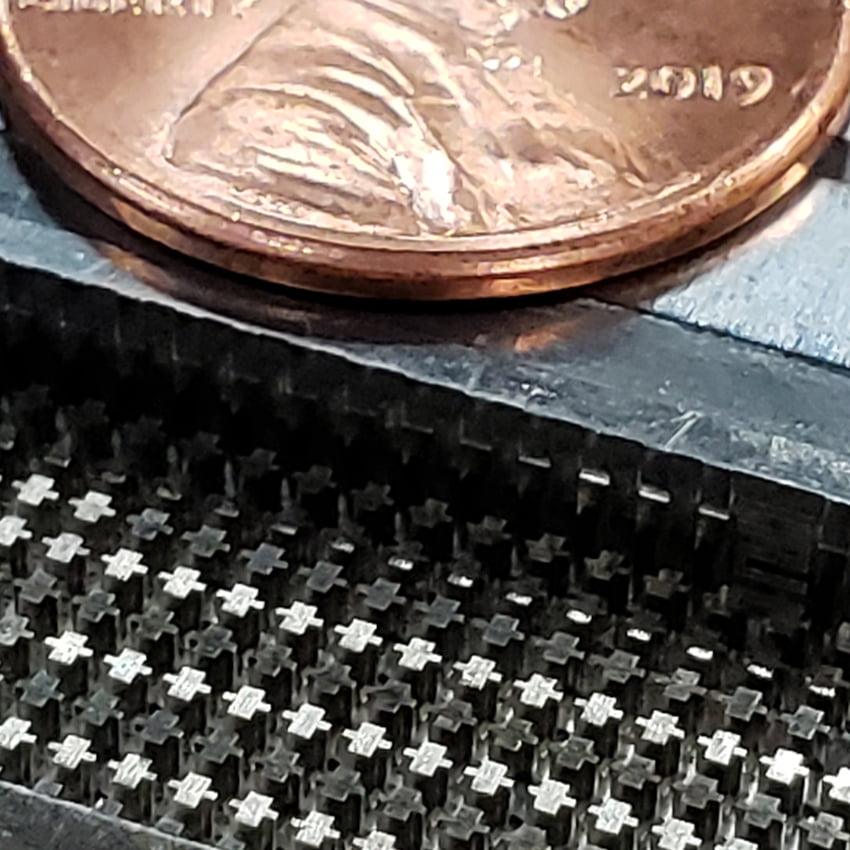

The ability to efficiently mold small intricate features is simply not possible using traditional tooling and plastic injection molding machines with conventional processing methods. In other words, specialized equipment is required to tool and mold challenging products. Deficiencies in equipment capabilities often times show up in unmet deliverables. Lead-times, quality and costs suffer. That is why Matrix continuously invests in industry-leading equipment and technology as you cannot produce difficult molded products if the proper tools are not available nor capable.

Technology Leader

We’ve established an excellent reputation in the marketplace with proven success tackling extremely difficult projects. As a full-service supplier, our equipment must keep pace with our customer’s quality and service expectations, especially as their product lines become more complex.

Matrix continues to heavily invest in cutting edge tooling technologies that support tight tolerance manufacturing. We are dedicated to purchasing the latest in Machining technologies, which recently include Wire EDM and CNC die sink EDM machining centers, as well as a high-speed CNC Milling Center used for graphite electrode construction and hard milling. We utilize high-end CAD software to support efficient product and mold design with integration capability into our CNC tooling technology. See more information of our recent Capital Equipment Investments on our News Page

Extremely capable, solutions-based leader in the Industry. We cannot compliment them enough regarding capability, quality and service.

Technology Partners

Equipment standardization is critical to what we do. As a result, Matrix has partnered with best-in-class equipment OEMs that share our values related to exceptional products backed by remarkable performance and service. Nissei, Sodick and AG Charmilles have been our suppliers of choice for the majority of our equipment needs. Matrix is considered a technology partner and domestic Beta test site for Sodick Plustech micro injection molding machines.

Purpose Built Facility

Our Molding Division is equipped with state-of-the-art injection molding machines to ensure process efficiency and repeatability. We have plant wide adoption of RJG, closed-loop production processing technology with real-time monitoring. Each injection molding cell is also complimented with the necessary support equipment to ensure an efficient molding operation. Support equipment includes material dryers, granulators, conveyors, water temperature controllers/ thermulator, chillers, automated part diverter chutes, oil temperature controllers, robotic sprue pickers, full-speed servo robots, automated inspection equipment and mold protection thermal cameras as required.

Lean, Efficient, Effective

All presses are outfitted with sight glass vacuum loaders, portable drying systems and separate vacuum loaders which are tied into a central solid state controlled vacuum system. Matrix Tool also utilizes a 5 ton and a 1/2 ton overhead crane and a closed loop central cooling tower system.

We maintain a controlled molding environment and coordinate all material handling, drying and process support activities in confined areas separated from the manufacturing area. Our facility is air conditioned and contains a fire control sprinkler system.

We put a lot of thought into our technology needs and facility layout so that our customers can maintain confidence in our ability to consistently meet their demands and tackle their toughest tooling and injection molding challenges! Learn more about our Precision Tooling or Injection Molding Capabilities.