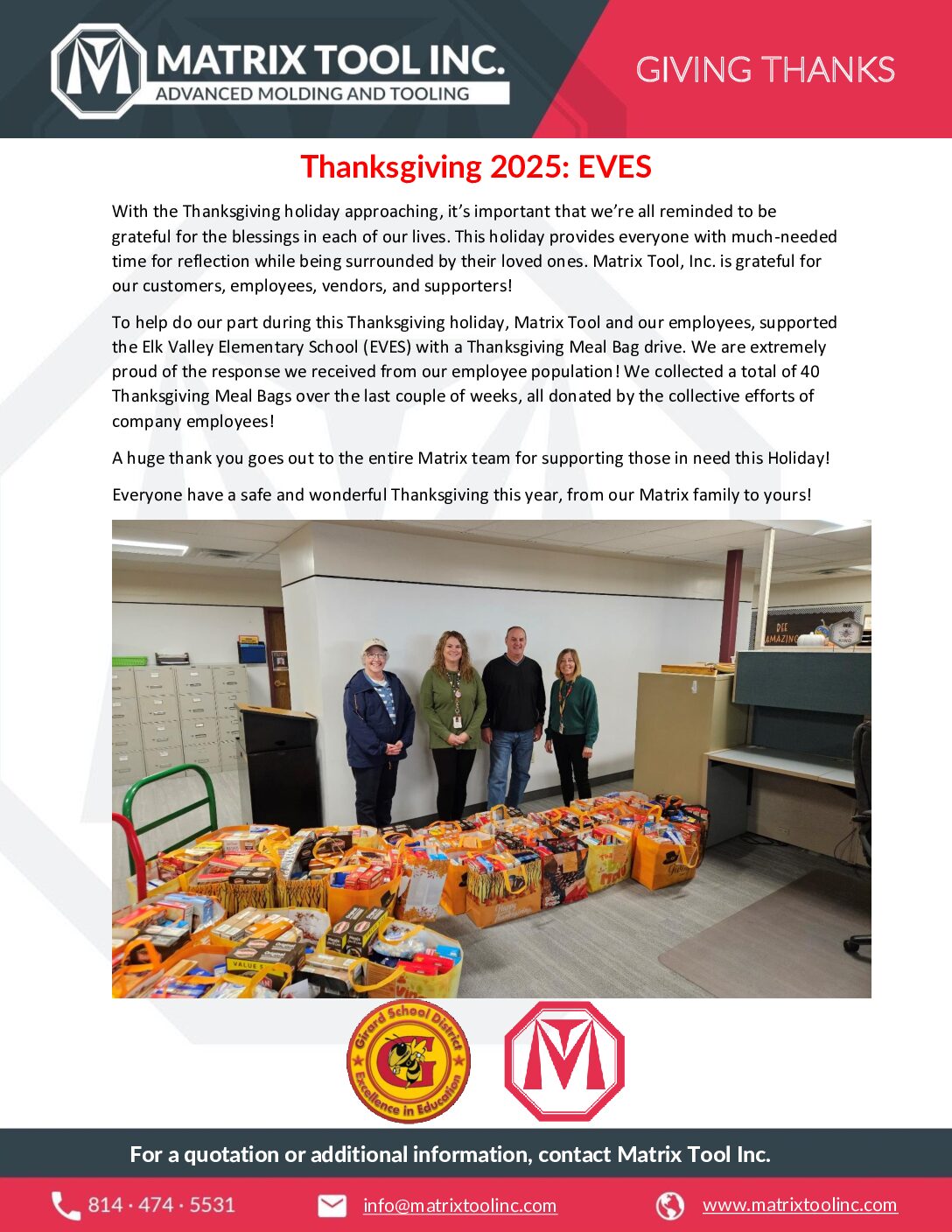

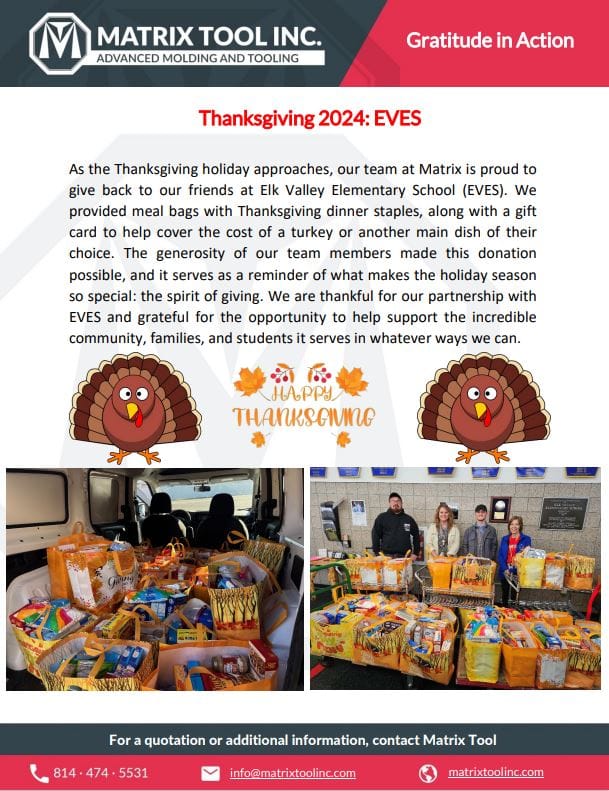

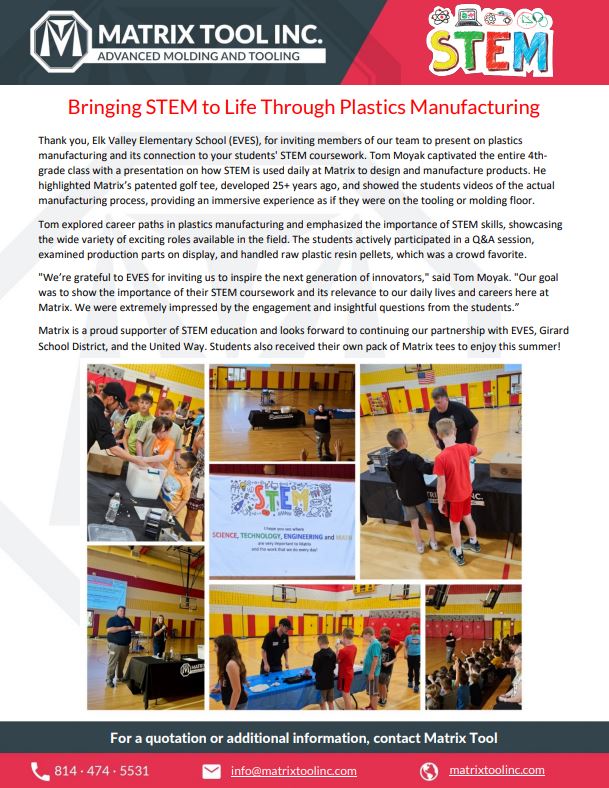

Increasing Capacity Through Advanced Injection Molding Investments Matrix Tool, Inc. is excited to announce the addition of two new 60-ton (clamping force) Sodick-Plustech high-precision injection molding machines (IMMs). These additions bring our total to (21) Sodick IMMs, including (14) micro-molding machines and (7) 60-ton presses, meaning half of our (42) in-house IMMs are now high-precision, fast-response Sodick machines. This milestone reflects our continued investment in advanced technology and our commitment to delivering the highest-quality components to our customers. The new … Read More